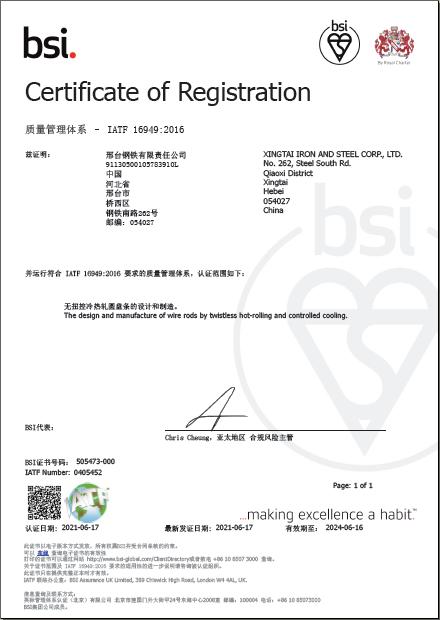

In June, Xingtai Iron and Steel Corp., Ltd. (hereinafter referred to as Xingtai Steel) successfully passes the recertification of QMS IATF 16949 (including IATF 16949:2016 and ISO 9001:2015) after being audited by third-party certification body BSI. So far Xingtai Steel has passed the Automotive Quality Management System certification for 14 consecutive years.

In order to improve the quality of products and enter the emerging automotive industry, Xingtai Steel started the ISO/TS16949:2002 (International Automotive Quality Management System) certification program in 2006 and passed the BSI (British Standards Institute) audit in the following year.

In order to ensure the effective implementation of the IATF16949 Automotive Quality Management System, Xingtai Steel has taken "continuous improvement, defect prevention, variation reduction and waste reduction" as the goal and continuously optimized the operation of the management system to promote the standardized management, process management and institutionalized management. In the 14 years since the introduction and implementation of the Automotive Quality Management System, spring steel, cold heading steel of automobile and other products are widely used in European, American, Japanese, Korean and domestic automobile industries. The steel for automobile fasteners has formed "Q" and "G" series, including 54 subdivided grades of cold heading steel for automobiles (passenger cars). At present, Xingtai Steel has obtained certifications from 38 automobile OEMs and parts manufacturers, becoming the steel enterprise with the most product certifications in China, and the sales volume of high-end certified products reached 52,000 tons last year.